MI-BOX containers for moving and mobile storage are the longest lasting, most durable containers available. They can be financed over 15 years and have been tested in every climate condition throughout the United States and Canada. Containers are the building blocks of any mobile storage business. They are the income producing assets of your business and part of the overall valuation of your business – now and years down the road. As your container inventory grows, so does your revenue and the value of your business. Invest into one of the most durable, longest lasting containers available and produce reoccurring revenue streams for the life of your business. 8′, 16′ and 20′ portable storage containers are available for our MI-BOX locations throughout the United States and Canada.

Specifications

MI-BOX portable storage container designs include composite wall panels for added durability, increased strength and reduced overall weight. Composite panels are proven to be longest lasting most durable surface for wall panels. It has been used in the transportation industry for decades. It does not rot, warp, fade or hold moisture. Our roof design is completely sealed to keep the weather out and the stored items safe and secure. The steel used on MI-BOX mobile storage containers is all hot dipped galvanized after the welding process. This has proven to be the most durable longest lasting finish available.

MI-BOX portable storage container designs include composite wall panels for added durability, increased strength and reduced overall weight. Composite panels are proven to be longest lasting most durable surface for wall panels. It has been used in the transportation industry for decades. It does not rot, warp, fade or hold moisture. Our roof design is completely sealed to keep the weather out and the stored items safe and secure. The steel used on MI-BOX mobile storage containers is all hot dipped galvanized after the welding process. This has proven to be the most durable longest lasting finish available.

- Innovative, high-quality features reduce maintenance costs, maximize capacity, and extend container life.

- Standardization of the manufacturing process ensures quality control. Time tested designs and materials make them the longest lasting portable storage containers in the industry.

- Hot dipped galvanized coating of all steel after the welding process for the most durable finish.

- Composite wall panels made from of a high-density polyethylene plastic core bonded between two high-strength steel skins.

- One-piece seam sealed and riveted aluminum roof

- Full width roll up doors or swing door optional

- ¾” flooring / max. span 24” to maximize load capacity

- Forklift tubes extend the full width of each container for safe and easy handling.

- Structural integrity allows for easy stacking up to 3 containers high. Stack them inside or outside.

- Integrated receiver tubes easily accept removable wheels for use with any roll off truck or trailer.

- Modular flat pack mobile storage containers are easy to assemble.

- 42 – 8 ft containers shipped on one truck (depending on manufacturer)

- 21 – 16 ft containers shipped on one truck (depending on manufacturer)

- 14 – 20 ft containers shipped on one truck (depending on manufacturer)

Sizes

-

8′ STORAGE AND MOVING VAULTS

- 7′ 10 ” long x 7′ 3 1/2″ wide x 7′ 10″ high

- Empty weight: 1,100 lbs.

- Forklift tubes 6″ x 3” – 30″ OC

- Composite wall panels

- 3/4″ flooring over 20” on center I beams

- One piece seam sealed and riveted aluminum roof panel

- Full width roll up door

- Stackable 3 high fully loaded

- Galvanized steel frames

- 42 – 8 ft containers shipped on one truck

-

16′ MOBILE STORAGE CONTAINER

- 16′ long x 7′ 3 1/2″ wide; 7′ 10″ high

- Empty weight: 1,900 lbs.

- Forklift tubes 6″ x 3″ – 48″ OC

- Integrated receivers for wheels

- Composite wall panels

- 3/4″ flooring over 24″ on center I beams

- Heavy Duty D-Rings Front and Rear

- One piece seam sealed and riveted aluminum roof panel

- Full width roll up door or swing doors optional

- Stackable 3 high fully loaded

- Galvanized steel frames

- 21 – 16 ft containers shipped on one truck

-

20′ MOBILE STORAGE CONTAINER

- 20′ long x 7′ 3 1/2″ wide; 7′ 10″ high

- Empty weight: 2,200 lbs.

- 2 – Forklift tubes 6″ x 3″ – 80″ OC

- 2 – Forklift tubes 6″ x 3″ – 48″ OC

- Integrated receivers for wheels

- Composite wall panels

- Recessed threshold

- 3/4″ flooring over 24″ on center I beams

- Heavy Duty D-Rings Front and Rear

- One-piece seamed sealed & riveted aluminum roof

- Full width roll up door or swing doors optional

- Stackable 3 high fully loaded

- Galvanized steel frames

- 14 – 20 ft containers shipped on one truck

Note: Specifications may vary depending on manufacturers. MI-BOX has three separate container designs and three separate manufacturers.

Shipping

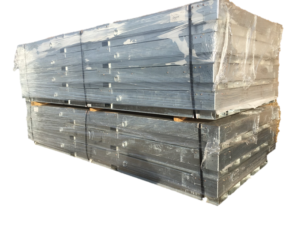

MI-BOX can ship up to 42 – 8 ft. units, 21 – 16 ft. units, 14 – 20 ft. units, or a combination of storage containers on one flatbed semi-truck from our US manufacturer. Roll up doors will be shipped separately. The containers will be in a flat-pack form. For unloading, we recommend using a minimum of a 15,000 lb. forklift. For example, this photo represents:

- 16-ft. containers in kit form

- Each 16 ft. unit weighs 1,900 lbs.

- Each stack of 7 weighs approx. 13,300 lbs.

- Total load weight approx. 40,000 lbs.

- Load range height approx. 98” – 102”

- Load width approx. 7’ 10”

- Load length approx. 16’ 6” per stack

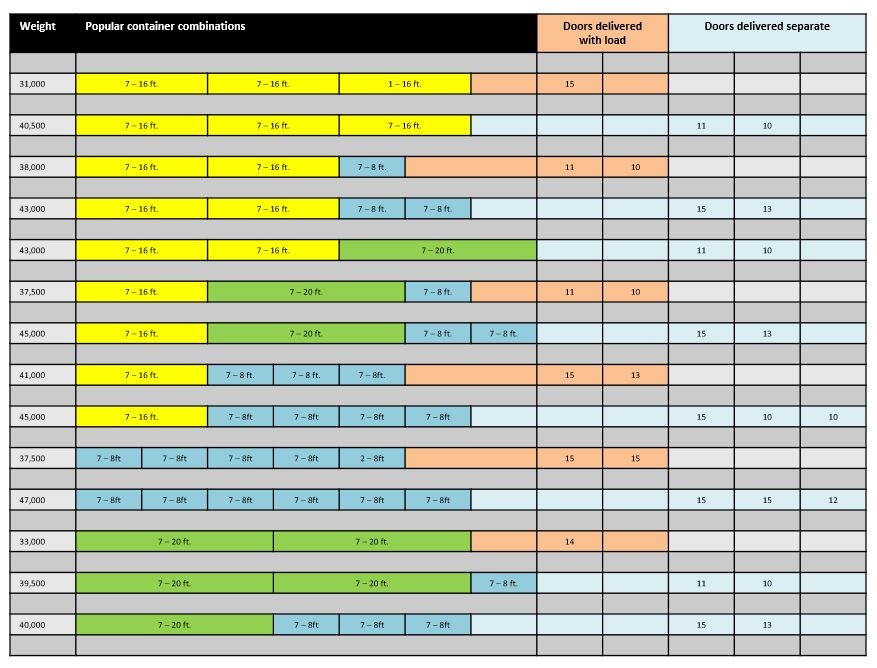

How Many Containers Can Ship on One Flatbed Truck?

Photos represent 21 – 16 ft. containers on a 53 ft. flatbed / total weight approx. 40,000 lbs.

Maximizing Flatbed Space (most common)

Shipping Quantities (click to download shipping quantities)

Shipping Quantities (click to download shipping quantities)

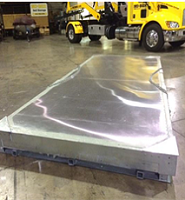

Assembly

MI-BOX Mobile Storage containers from the US are shipped on flatbed trucks in flat pack units so you will need a forklift to unload them. The containers will be in a flat-pack form in stacks of 7 for most loads. To assemble containers, we provide a complete set of assembly instructions. You will then go over the instructions via phone or in person with a MI-BOX member who actually put many of these containers together. If you have additional questions while assembling containers, you may call a MI-BOX member 7 days a week for immediate answers. It should take a few guys about 1 hour to complete the assembly once you get the hang of it. We also offer two other manufacturers from outside the US which will ship in ISO containers. Depending on which containers you choose, shipping and assembly may vary by manufacturer.

1Layout the Unit

1Layout the Unit 2 Raise the Roof

2 Raise the Roof 3 Raise Front Door Frame

3 Raise Front Door Frame 4 Rear Wall Frame

4 Rear Wall Frame 5 Lower Roof

5 Lower Roof 6 Raise Right Wall

6 Raise Right Wall 7 Raise Left Wall

7 Raise Left Wall 8 Tighten All Bolts

8 Tighten All Bolts 9 Install Door

9 Install Door

Compare Containers

At first glance, all mobile storage containers may look alike. They’re not. With a closer look you will start to see differences that will affect the longevity of the containers and therefore the overall value of your investment. Get containers that are build to last the life of your business. Get quality containers. GET MI-BOX. For a closer look at some of these differences, please click here.